25 Years in Business

Butcher Block

Find the Top Butcher Block in Escondido, CA

Every chef wants butcher block countertops in their kitchen. You will never have to use a cutting board again! Butcher block adds warmth and timeless beauty to your kitchen. It can easily blend well with any design taste; from traditional to vintage to rustic to contemporary. Butcher block countertops are made out of thick strips of hardwood glued together to form one solid piece. Popular wood choices for butcher block countertops are maple, oak, cherry, and walnut, but any type of wood can be made into a butcher block countertop. When considering butcher block countertops, you need to decide if the countertop is for aesthetics or if you intend to cut on them. A butcher block that is sealed cannot be used for cutting directly on and will allow water damage to occur. The knife can ruin the sealer and leave scratches that cannot be easily sanded away. The sealer, however, does protect the countertop from water and helps the wood to maintain an even color. An unfinished or oil-finished butcher block is the best choice for cutting and chopping. Any stains or scratches on the countertop can be sanded away. A disadvantage of an unsealed butcher block is that it can warp or turn black from excess water, so areas near the sink and water supply should be sealed.

Get a Free Estimate

Designing a Custom Countertop

Choose a Wood Species

Choose a Sealer

Choose a Construction Style

Choose an Edge

Step 1. Choose a Wood Species

Walnut / Black Walnut

American Cherry

Hard Maple / Hard Rock Maple

Hickory

Sapele

Weathered White Oak

Step 2. Choose a Sealer

We offer 3 wood sealers to accommodate any situation. Still struggling to decide? Check out our quick reference sheet for a side-by-side comparison.

Rubio Monocoat

Ideal for working kitchens with sinks. The Rubio Monocoat sealer is our recommended sealer for wood countertops (with or without sinks) because you can cut on the surface, it’s easy to repair, and provides a high level of protection.

- 100% VOC free

- Penetrating wood sealer that protects from the inside

- Gives the wood a natural look and feel

- Easy to repair

- Water resistant (works great on tops with sinks)

- Stain resistant

- OK to cut on

- Safe for food contact

- Smells like bees wax when first applied

Polyurethane

A durable top coat perfect for table tops and bar tops. Polyurethane is an very hard, water resistant finish that doesn’t smother the wood’s natural texture. Ideal for both residential and commercial wood surfaces. This is our recommended finish for table tops and bar tops.

- UL Greenguard Certified

- Scratch resistant

- High degree of water resistance

- High stain resistance

- Available in matte and satin sheen

- Safe for food contact

Butcher Block Wax

Used on butcher block tops and cutting boards. The only product recommended for use on butcher block countertops which will be cut on.

- 100% food safe certified

- Ideal butcher block tops and cutting boards

- Smells great

Step 3: Choose a Construction Style

There are three styles to choose from, each with it’s own look, and in some cases function.

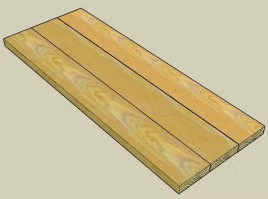

Plank/Face

Plank/Face is a design and cost driven construction style. It has the look of furniture and because labor/scrap is minimized it is the most cost effective of the three styles. The boards are typically between 4”-6” wide and run the full length of the top. For most species thicknesses of up to 1- 3/4” is the maximum available.

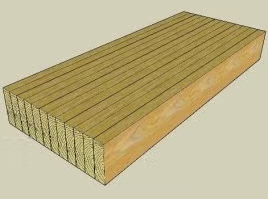

Edge Grain

Edge grain is a construction style where the top surface of the countertop is the edge of the board, as seen below. The boards are typically 1-3/4” wide and run the full length of the top. Thicknesses of up to 4-1/2” can be achieved with this style. Historically this is the look people think of when using the term “butcher block”.

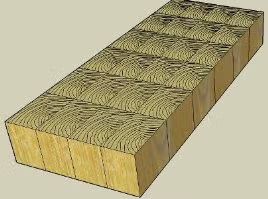

End Grain

End grain is another construction style that is very popular for butcher blocks, chopping blocks or food preparation areas. Here, a piece of wood is stood on its end giving the surface a checkerboard look. Some end-grain construction countertops are subtle, using the same wood species to form a tone-on-tone offset checkerboard, while others are more dramatic and use contrasting dark and light woods to form a very visual checkerboard. The blocks are typically 1-3/4” x 1-3/4” with thicknesses of up to 4-1/2” achievable.